BASF launches localized e-mobility coolant concept for EVs in China

Introduction: BASF’s Big Bet on China’s EV Boom

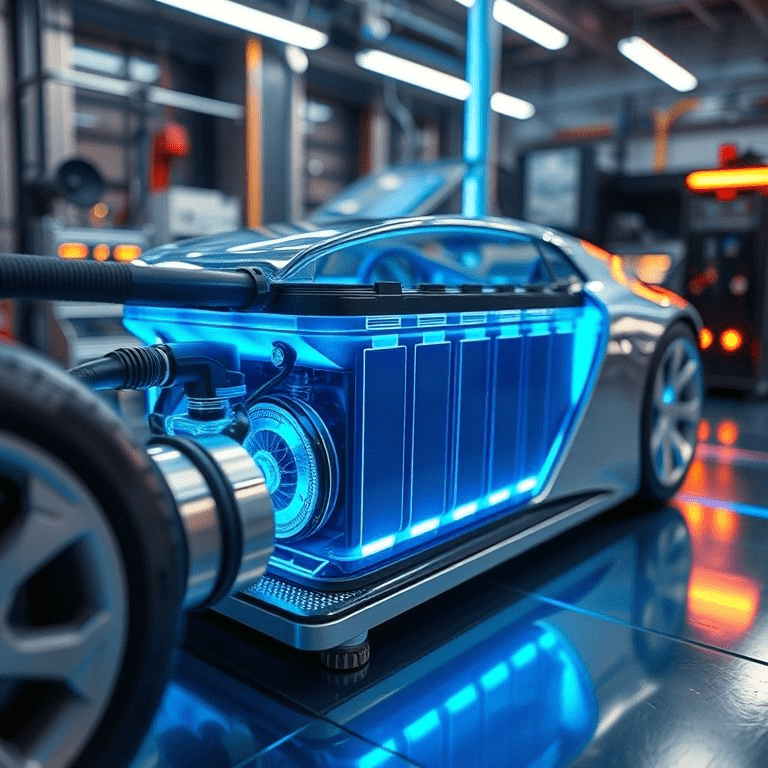

China is the world’s largest electric vehicle (EV) market, accounting for more than half of all global EV sales. As adoption accelerates, so does the demand for advanced materials that can make EVs safer, more efficient, and longer-lasting. On September 11, 2025, BASF announced the launch of its Localized E-Mobility Coolant Concept (LECC) specifically designed for China’s growing EV sector. This marks a significant milestone in BASF’s strategy to strengthen its footprint in Asia while addressing one of the most critical challenges in electric mobility—thermal management.

Thermal management plays a vital role in electric vehicles. Efficient cooling ensures battery safety, prevents overheating, extends battery lifespan, and improves performance under varying weather conditions. BASF’s new LECC is not just a product launch—it represents a strategic pivot towards local innovation in the largest EV market in the world.

In this detailed report, we explore the technology behind BASF’s LECC, industry reactions, its implications for automakers and consumers, and the broader outlook for EV materials innovation in China and beyond.

Why Thermal Management Matters in EVs

Before diving into the LECC, it’s essential to understand why cooling solutions are so critical in EVs. Unlike internal combustion engine (ICE) vehicles, where heat is managed through traditional radiators and fluids, EVs have multiple components that require precise temperature regulation:

- Battery Packs – Lithium-ion batteries are sensitive to both heat and cold. Excessive heat can trigger thermal runaway (a chain reaction that leads to battery fires), while cold reduces efficiency and range.

- Power Electronics – Inverters, converters, and onboard chargers generate significant heat that must be dissipated to maintain performance.

- Electric Motors – Motors can overheat under heavy loads, especially in commercial vehicles and high-performance EVs.

- Charging Infrastructure – Ultra-fast charging (350kW+) creates rapid heat buildup that needs efficient cooling.

Poor thermal management not only shortens battery life but also increases safety risks. According to China EV100 Forum data, 27% of EV incidents between 2018 and 2023 were related to thermal issues. BASF’s LECC directly addresses this challenge.

Inside BASF’s Localized E-Mobility Coolant Concept (LECC)

BASF’s LECC is designed with China’s unique EV environment in mind. Unlike global, one-size-fits-all coolants, LECC adapts to local manufacturing, climate conditions, and regulatory frameworks. Key features include:

- Localized Formulation

- Developed in BASF’s Shanghai Innovation Campus.

- Uses locally sourced raw materials to reduce supply chain costs and emissions.

- Meets China’s GB/T battery safety standards and NEV (New Energy Vehicle) regulations.

- Enhanced Battery Safety

- Provides non-flammable properties to reduce risks of battery fires.

- Contains additives that stabilize battery temperatures during ultra-fast charging.

- Extended Vehicle Range & Efficiency

- Reduces internal battery resistance by maintaining optimal operating temperatures.

- BASF claims LECC improves EV range by 4–7% compared to conventional coolants.

- Sustainability

- Recyclable and less toxic than traditional glycol-based coolants.

- Designed for compatibility with circular economy practices.

- Adaptability

- Works with both liquid-cooled batteries and emerging immersion cooling systems, giving automakers flexibility.

Industry Reactions

BASF’s LECC launch has drawn attention from automakers, analysts, and government stakeholders.

- Automakers in China: EV leaders such as BYD, NIO, XPeng, and Geely are expected to evaluate LECC for integration into next-generation models. A BYD insider quoted by China Daily noted that “thermal management is becoming a critical differentiator in EV performance—solutions like BASF’s LECC could give us an edge in fast-charging efficiency.”

- Analysts: According to Bernstein Research, the market for EV cooling fluids in China is projected to reach $3.5 billion by 2030, growing at 25% annually. BASF’s localized approach gives it a “first-mover advantage” over Western rivals like Dow and Eastman.

- Government: With China’s push for carbon neutrality by 2060, officials view advanced EV materials as a key enabler. The Ministry of Industry and Information Technology (MIIT) welcomed BASF’s innovation as a step toward safer, greener EV adoption.

Competitive Landscape: BASF vs. Rivals

BASF is not the only company eyeing the EV coolant market, but its LECC has several differentiating factors:

- Dow Chemical: Offers a global EV coolant line but relies heavily on imports to China.

- Eastman Chemical: Focuses on North American automakers.

- Chinese Players: Local firms like Sinochem and Guangzhou Tinci are developing domestic solutions but lack BASF’s global R&D scale.

By leveraging its Shanghai Innovation Campus, BASF is combining global expertise with local execution, giving it a competitive edge.

Impact on China’s EV Market

The LECC launch could influence multiple aspects of China’s EV ecosystem:

- Safety Standards – Adoption of LECC could reduce thermal incidents, bolstering consumer confidence.

- Fast-Charging Infrastructure – With EV makers racing to deploy ultra-fast charging stations, LECC’s cooling properties could support this transition.

- Cost Efficiency – Local sourcing reduces costs for OEMs, which may trickle down to EV pricing.

- Global Exports – Automakers in China could leverage BASF’s LECC to meet safety standards in export markets like Europe and the U.S.

Expert Commentary

“Thermal management is the hidden backbone of EV safety and performance,” said Dr. Lin Qiang, a battery expert at Tsinghua University. “BASF’s localized solution could set a new benchmark, especially as China scales up ultra-fast charging networks.”

Eva Peters, BASF’s Vice President of E-Mobility Solutions, emphasized that “China is not just the largest EV market; it is also the most dynamic. Our LECC reflects BASF’s philosophy of innovating where it matters most—close to customers, close to end-users, and aligned with sustainability goals.”

Future Outlook

Looking ahead, BASF plans to expand its LECC offering across Asia and potentially adapt it for hydrogen fuel cell vehicles, which also require advanced thermal solutions. With EV adoption expected to exceed 60% of new car sales in China by 2030, demand for localized, high-performance coolants will only grow.

BASF’s move could also spur a wave of R&D collaborations between chemical giants and automakers. Similar to how semiconductors shaped global supply chains, advanced EV materials may become the next strategic battleground.

Conclusion

BASF’s introduction of the Localized E-Mobility Coolant Concept is more than just a product launch—it’s a strategic statement. By tailoring advanced thermal management solutions for China, BASF is positioning itself at the center of the world’s fastest-growing EV market. As competition heats up, solutions like LECC could determine which automakers—and which countries—lead the next phase of the electric mobility revolution.